ACCUPRINT™

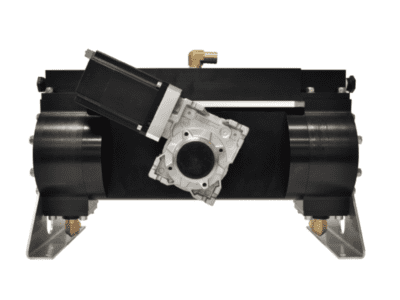

DUAL BLADE CHAMBERED INK SYSTEM

STREAMLINED MAINTENANCE FOR EXCEPTIONAL GRAPHICS

For superior graphics using quality inks and substrates, AccuPrint™ is the corrugated ink system of choice. SUN Automation Group’s® flexo ink-metering system protects ink from the harsh factory environment to improve ink quality and performance.

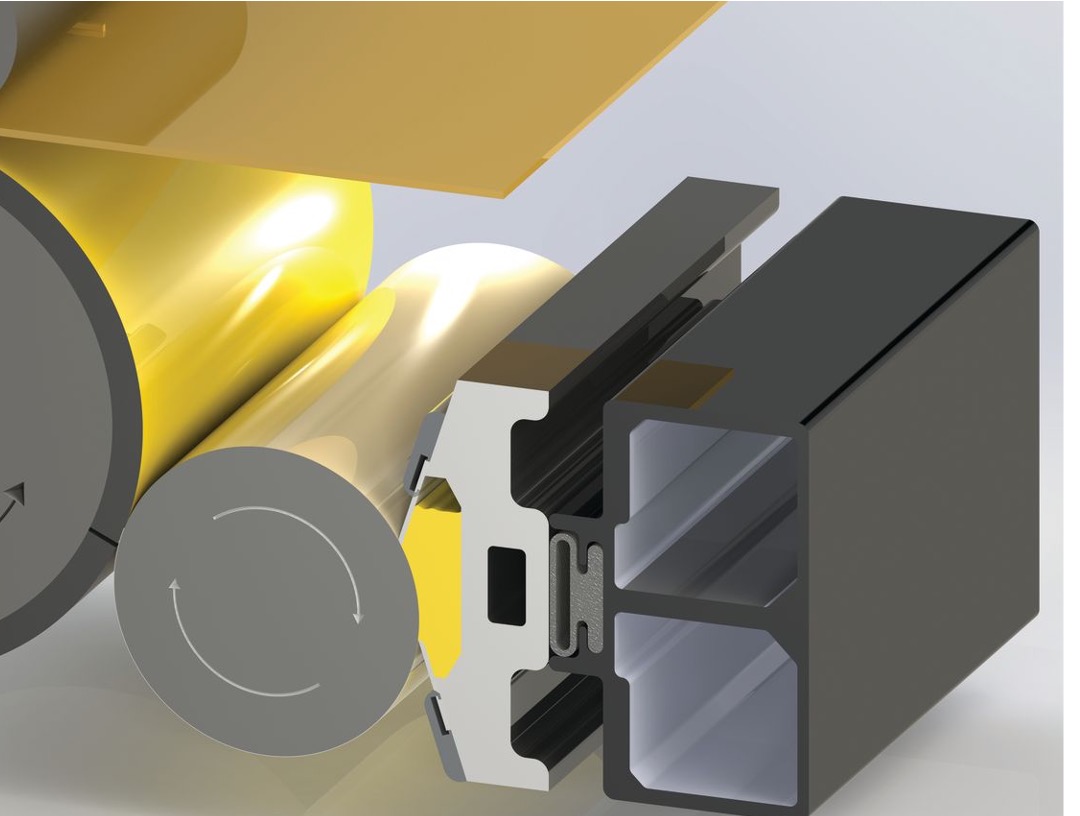

Superior Graphic Quality

The system is designed for optimal usage of quality inks and substrates, leading to superior graphics.

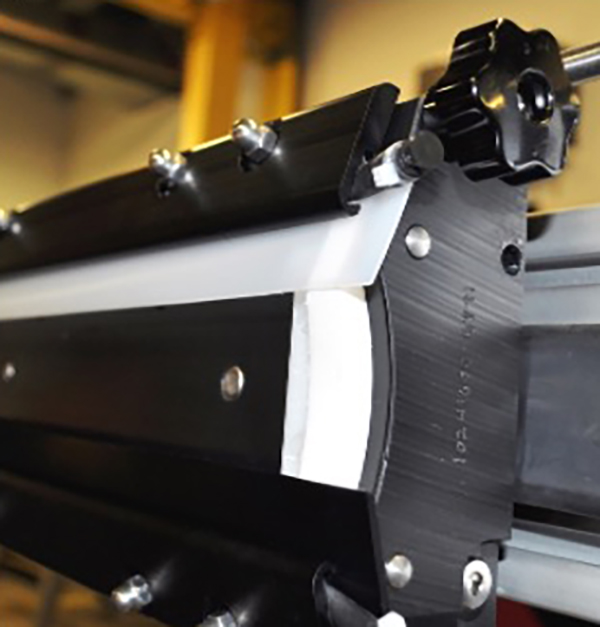

Tool-less Blade Replacement

AccuPrint’s tool-less blade holder allows for quick and easy blade replacement, minimizing downtime.

Advanced Wash-Up System

This feature prevents clogging of the system and ensures quick ink recovery, leading to more efficient operation.

Dust and Particle Protection

The fully enclosed chamber system keeps out dust and particles, preserving the quality of the ink and overall print results.

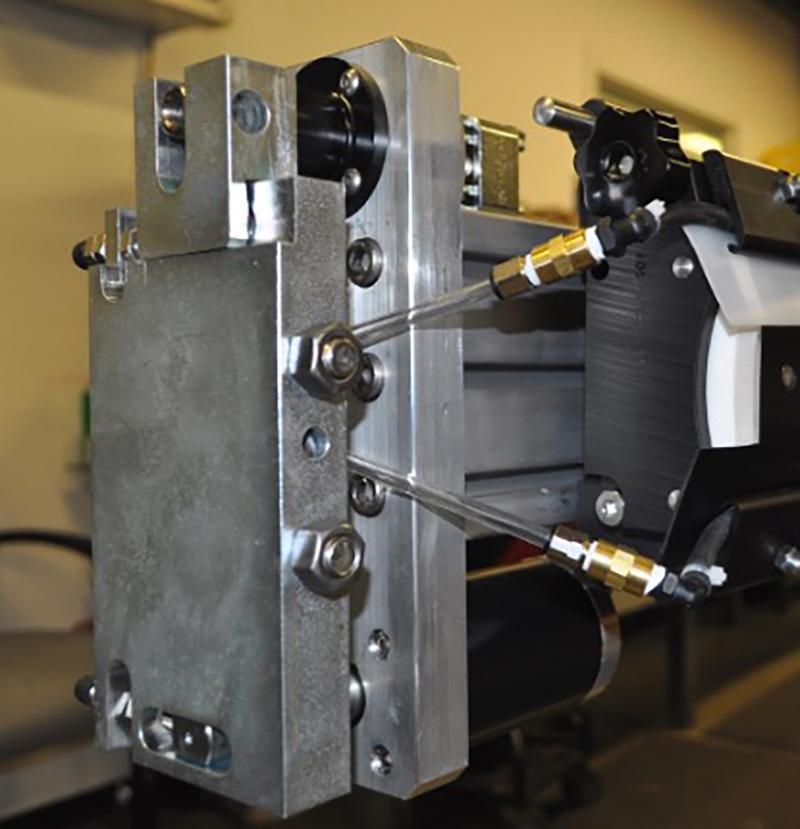

Easy Maintenance

The end seals can be easily and quickly replaced, and the optional Anilox roll drive provides precise speed control, simplifying maintenance tasks.

Resource Efficiency

Compared to traditional systems, AccuPrint™ can significantly reduce setup time, ink waste, and water usage, leading to cost savings and environmental benefits.

FAQS

- Blade & end seal life = 80 hours

- Wash cycle = 7 minutes & 8 gallons of water

RELATED PRODUCTS

ColorMaster® Single Blade Ink System

The ColorMaster by SUN is an advanced roll-to-roll flexometering system designed to provide uniform blade loading and precise ink-metering across the surface of the anilox roll.

Electra-Flow Electric Ink Pump

sing a low-voltage DC motor in a cycloidal motion to oscillate opposed diaphragms, Electra-Flow™ eliminates air consumption (added stress to the compressor), fittings, tubing, and solenoids.