As corrugated packaging designs become more intricate in request, the die cut section of your converting machine can make the difference between a corrugated POP and a corrugated FLOP. Whether it be automatic packaging lines, trays, retail ready packaging, or display work, high quality corrugated design requires a persistent eye on perfection. A die cut section equipped with sharp tooling, precise registration, speed control and a consistently smooth anvil blanket is needed to create these modern corrugated jobs. However, according to market surveys, Retailers believe converters need to produce better, cleaner perforations to improve packaging functionality and appeal.

Anvil Trimmers are a great solution to improve die cut accuracy and cut consistency – along with its many other benefits. Here are four reasons corrugated converters have invested in the SUN MicroGrind® Anvil Trimmer:

#1. Improve Die Cut Consistency

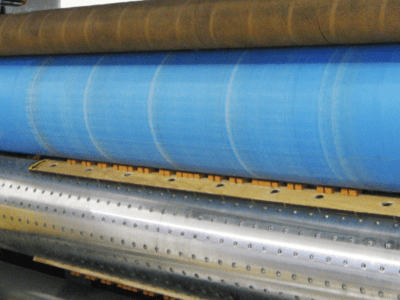

Having a uniform surface throughout the life of the anvil blanket is key to producing accurate die cuts, nicks and scores, from the first board to the last. However, the anvil’s surface can become compromised due to the constant blow of the cutting die during production. Dips and valleys may begin to take shape in your anvil blanket and this uneven surface is the prime culprit of improper or incomplete die cuts. To trim the anvil back to a uniform surface, MicroGrind® uses a heavy duty tungsten carbide roll to automatically grind precisely .001” of material from the anvil blanket, every 5,000, 10,000 or 15,000 sheets. This micro-grind to the surface keeps the anvil cover flat and true, creating proper knife-to-anvil contact which leads to precise cuts and pleased customers.

#2 Control the Anvil Speed

For machines with an independently driven anvil drum (servo or vector-drives), it is important for your anvil to match the speed of the die cut to avoid inaccurate cut lengths. Thankfully, MicroGrind® can integrate with most existing speed compensators. Once contact has been made with the anvil blanket, the MicroGrind® Anvil Trimmer will calculate the anvil speed and then recalculate after each subsequent grind. This information sends directly to the existing independent drive control system, thus providing for accurate speed control throughout the life of the covers. Anvil speed management is a huge factor and controlling it means your customers get the same size box, every time – new blanket or old. For machines that don’t have an existing speed compensation, SUN can provide in most cases and will function as noted.

#3 Proper Scrap Ejection & Waste Reduction

When you have improper cuts, due to a rugged anvil blanket, scraps are not ejecting properly from the board. And as you know, leftover scraps can cause several frustrations for you and your customers. Jammed packaging lines, dysfunctional perforations and confusing or laborious shelf appeal are some of the scrap-related reasons your customers may begin turning to your competitors. But with MicroGrind® keeping the anvil smooth, the equation is simple: uniform anvil + effective tooling = accurate die cuts – board scrap. And that’s what happy customers want.

#4 Extend Tool Life & Machine Care

As operators begin to notice the inconsistent die cuts across the board, a common and quick way they troubleshoot is by applying more pressure to increase contact to the anvil blanket. Easy, right? Not if the problem is the surface of the anvil – increasing pressure can harm multiple components of the machine! For instance, with an increase in pressure, the area of knives that were already performing well can be damaged by the unnecessary force (while the tooling not penetrating earlier may be fine), the anvil blanket can be corrupted even more and overall more stress is placed on the machine. With MicroGrind® grinding the anvil cover without operator intervention, operators no longer think to over-pressure the machine to compensate for imperfections in the anvil – since there are none. This extends tool life and relieves stress on your machine, reducing costs in equipment maintenance or break downs and tooling replacements.

With SUN Automation’s MicroGrind Die Cut Accuracy system, you’re not only investing in a quality anvil trimmer, you receive a full system engineered to eliminate the rotary die cutting variables that impact sheet length, scoring, scrap ejection and machine/tooling life. MicroGrind is available for both top and bottom anvil configurations and is compatible with many original equipment manufacturers. The ability to produce retail-ready packaging, POP displays, shelf-ready trays and more commands a die cutter or flexo folder gluer up for the challenge. Request a quote for a MicroGrind unit today and a SUN representative will contact you with more information.

MicroGrind® Anvil Trimmer [InfoGraphic]

MicroGrind® Anvil Trimmer [InfoGraphic]