Data Science is the ability to take raw data, from a wide array of sources, and make it useful, actionable and valuable. Data science, IIoT and Machine Learning have recently come to the forefront of the technology revolution in corrugated, bringing unprecedented insight into the production floor and beyond. Though IIoT (Industrial Internet of Things) technology has been around for decades, IIoT technology custom to corrugated converting applications is just starting to enter the industry. As we step into this new territory, it is important to understand how these technologies work to fully capture the value it can bring to the future of your operations.

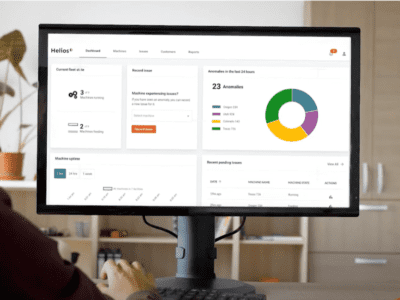

In 2021, Sun Automation unveiled a new corrugated IIoT platform, Helios – expert-driven IIoT and machine learning technology tailored to the needs of the corrugated industry. In developing this platform, we invested our time and resources into data science, IIoT and machine learning and what it could mean for the future of corrugated converting.

Here’s a brief overview of how these technologies work and the relationship they share with the success of your organization.

Live Monitoring

The first step to data science is capturing the data. To capture important data in corrugated, robust sensors and trackers are used to quantify your converting operations into numbers. Components such as the machine’s PLC, heat sensors, speed sensors, tracking software, and other data-capturing hardware help to create a clear picture of your operations in real time. During the live monitoring stage, the IIoT technology will capture and store the machine’s data and present this data to you through visual dashboards.

Since data science is only useful if the data it first captures is clear and accurate, it is important to check the integrity of your live monitoring system regularly to ensure the data it captures is indeed true. Though it is the most basic stage of data science, live monitoring is the foundation for the more complex, smart technologies to come.

Machine Learning

Humans learn to identify and navigate the world around us through experiences and recognizing patterns, often taught to us by others (like parents, teachers, mentors) – machines can now do the same. As technology advances, IIoT platforms have acquired a higher level of logic and intelligence, through data science, allowing the software to learn how to segment the data into useful information, supervised and unsupervised.

Unsupervised Learning

As your IIoT platform begins monitoring the equipment live, it starts to understand the normal productivity levels, speed, temperature, alignment, and general quirks of the machine, on its own. Once the platform is aware of the normal patterns of your equipment, it becomes skilled to flag data that deviates from the norm. Without user input, the technology can tell which components deviated from their normal speed, temperature, alignment etc. at a specific point in time – hence “unsupervised learning”. Though the software has not yet learned what the anomaly means, it knows the metrics are out of the norm from what it traditionally records on that machine, and it brings the deviation to your staff’s attention.

As anomalies are flagged, production staff become more aware of the factors affecting the productivity, efficiency, and safety of their equipment, helping to prevent and minimize downtime. At this stage, anomaly detection is the first tier of IIoT intelligence – simply recording anomalous data with a question mark. Combined with the knowledge of a veteran operator, that is when supervised learning begins and the power of IIoT comes full circle.

Supervised Learning

Supervised learning takes IIoT platforms to a new level of intelligence, through user input. Just like veteran operators become masters of machines after decades of listening, tinkering, and learning, the more the platform observes and interacts with your machine and staff, the more valuable the data science becomes. As downtime and flagged anomalies occur, your staff can label the recorded data as events such as maintenance intervals, known equipment failures, sheet jams etc. in the platform. Combine this operator-labeled data with the metrics from the machine, and the IIoT platform will learn to identify the patterns that lead to known events and can notify operators of expected downtime. This level of artificial intelligence can provide insight to improve maintenance schedules, part procurement and ultimately equip your staff for maximum productivity and minimum downtime.

As anomalies are identified, solved, and labeled in the IIoT platform, through supervised and unsupervised learning, your current and future operators become more equipped with the knowledge they need to better manage the ups and downs of your unique operations. Machine learning is unique to each asset in your fleet and the data models are trained specifically to your operations, creating an intelligent digital blueprint for the success of your equipment. That is the beauty of data science and machine learning, the more experience the platform has with your equipment and staff, the smarter it becomes.

The Future of the Corrugated Industry

Data science and machine learning technologies could easily be the solution to many common pain points in the corrugated industry. With its ability to report data not readily understandable, identify the source of problems without operator intervention and predict machine failures from legacy data, an IIoT platform provides incredible opportunity for increased uptime, improved performance and a high ROI. Solidifying your future starts now. Since operator interaction with the IIoT platform is so critical to prevent future downtime, the time to invest in an IIoT solution is soon – before your veteran operators retire, so this recordable data is used for machine learning and benchmarking your equipment.

We believe the future of the corrugated industry involves personalized, artificial intelligence that works alongside your production staff to create the most intelligent, efficient and profitable systems. We believe, the future is Helios. Learn more about the Helios IIoT Platform, powered by Sun Automation, and calculate your ROI to see how data science and machine learning could impact your future in the corrugated industry.

Release Notes: Tiger Artemis Sprint 1

Release Notes: Tiger Artemis Sprint 1