Feeding Backstop Table

Efficient Sheet Handling

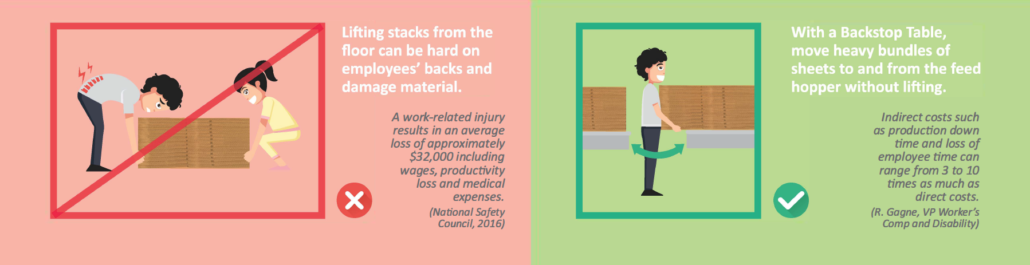

SAFETY & EFFICIENCY FOR CORRUGATED PRODUCTION

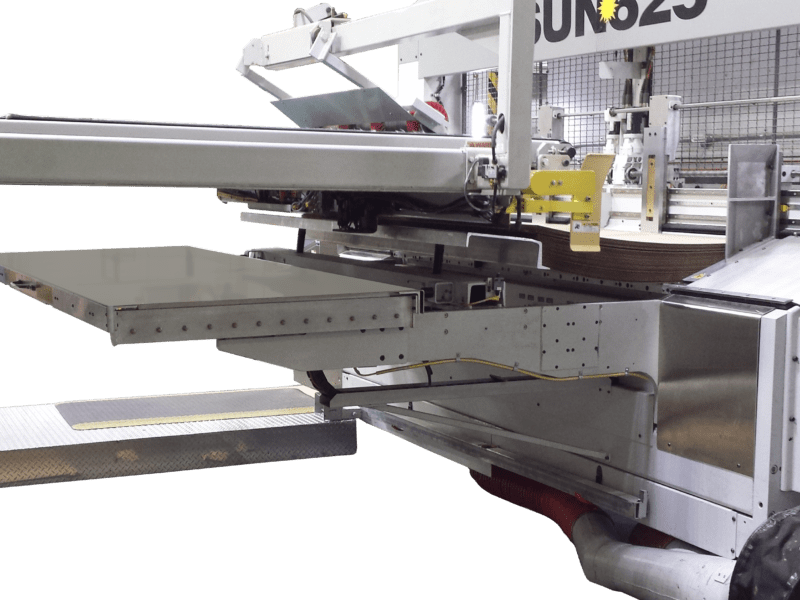

The Backstop Table by SUN Automation Group is an ergonomically designed accessory for SUN’s lead edge feeders, facilitating easier unloading and reloading of the feed hopper, clearing of jams, and preparation for setup. The table enhances operational convenience, promotes safety by reducing heavy lifting, improves efficiency by simplifying processes, and minimizes material loss by providing a flat, elevated surface for boards.

Optimized ergonomics

The Backstop Table is designed at board line height, reducing the need for operators to bend excessively or lift heavy bundles of sheets.

easier and more convenient operation

Located next to the hopper at board line height, operators can move small bundles of sheets from the hopper to the Backstop Table. It makes clearing a jam, pulling out bad sheets, and reloading the hopper a smooth process.

Increased efficiency

The table simplifies the process of unloading the hopper, clearing feed end jams, or removing bad sheets from the stack. It ultimately saves time and labor, reducing worker fatigue and improving efficiency.

seamless integration

The Backstop Table is designed to be retrofitted to all SUN lead edge feeders operating with a pre-feeder, making it a flexible addition to different machines.

reduced waste

Instead of placing the board on the floor where damage can occur, the Backstop Table provides a clean, flat, elevated surface for placing the board, reducing potential material loss.

enhanced workplace safety

The Backstop Table helps to prevent injuries, fatigue, and frustration in the workplace by eliminating the need for operators to lift heavy bundles of boards. It contributes to a safer work environment.

FAQS

- Support table with safety in mind.

- Moves with Backstop In-Out

RELATED PRODUCTS

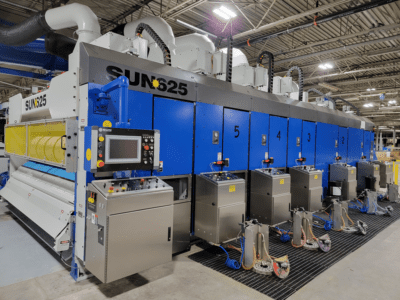

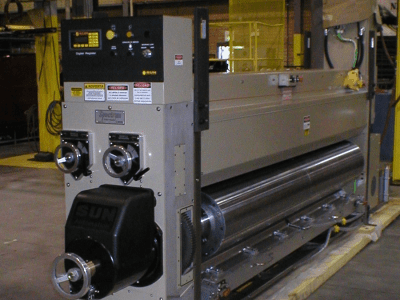

SUN625HD® Heavy-Duty Rotary Die Cutter

Proprietary, proven systems, specially formatted to maximize printing and heavy duty die-cut assembly and production.

Spectrum® Corrugated Inside & Outside Print

Whether you aim to deliver personalized messaging, reinforce your brand identity, or enhance the unboxing experience, Spectrum Print offers a seamless and efficient way to bring your vision to life.