Helios

Revolutionizing Corrugated Quality Control

OPTIMIZING PERFORMANCE & PROFITABILITY FOR CORRUGATED AND CONVERTING

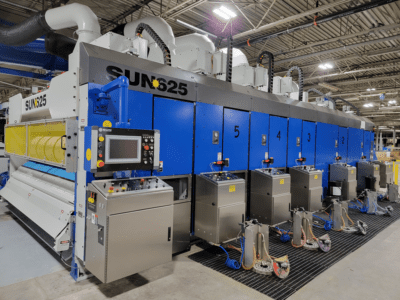

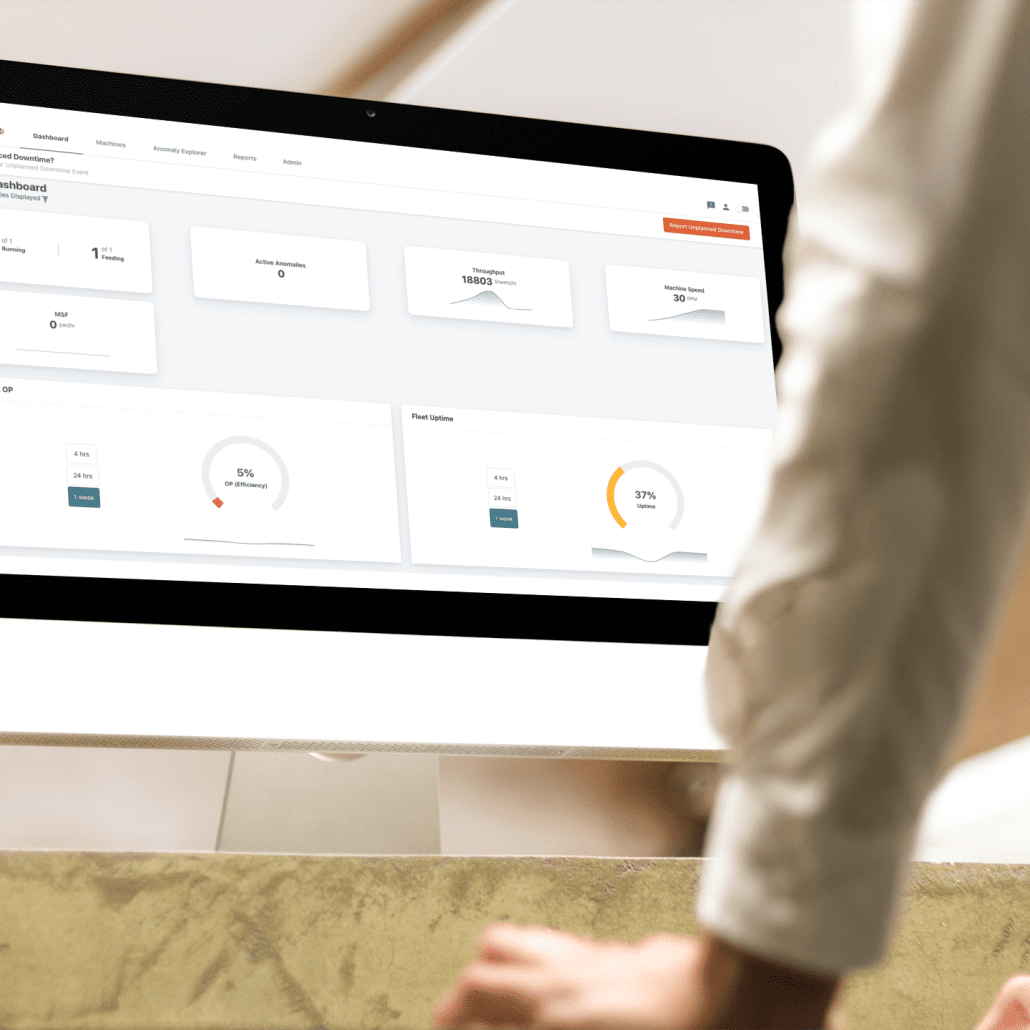

Helios is an innovative Industrial Internet of Things (IIoT) solution, designed to provide unprecedented data and control to customers throughout the corrugated converting industry. The unique, machine-agnostic solutions allow anybody, industry-wide, to access actionable insights, optimize maintenance, and reduce downtime, no matter what brand of machine equipment they use at their facilities. Helios is an idea spun off by SUN Automation Group, a corrugated converting industry leader in innovative solutions and aftermarket support and services. Since 1986, SUN has led the way for automotive production solutions in the corrugated manufacturing space. The new platform-agnostic Helios solution further cements this goal and differentiates SUN as a world leader in aftermarket support.

Boosted Plant Productivity

Helios enhances plant productivity by systematically analyzing production bottlenecks and providing intelligent solutions to resolve them. Through continuous monitoring and AI-driven insights, it identifies potential challenges and areas for improvement, leading to better utilization of resources and more efficient operations.

Minimized Unplanned Downtime

By utilizing predictive maintenance algorithms and proactive parts ordering, Helios keeps machines running smoothly, reducing downtime. Machinery can be maintained before critical failures occur, and necessary parts are available exactly when needed, resulting in reduced unplanned stoppages and more predictable operational flow.

Maximized Output

Helios allows for optimal utilization of assets through improved maintenance and failure prediction. By understanding the exact time to change key parts and providing real-time notifications of potential anomalies, it enables the maintenance team to work proactively rather than reactively, ensuring machinery is consistently operating at peak efficiency.

Prevention of Machine Failures

Helios predicts and prevents machine failures through real-time monitoring and intelligent analysis. It detects subtle anomalies that might be imperceptible to human operators and takes corrective actions or alerts the maintenance team. This proactive approach prevents costly disruptions and ensures consistent product quality.

Streamlined Operations

Through automated parts ordering facilitated by Helios, necessary parts are always available, reducing operational delays. By connecting directly to the inventory system and understanding usage patterns, Helios ensures that parts are on the shelf for quick recovery, minimizing the carrying cost of extra inventory and enhancing operational responsiveness.

Improved Operator Performance

Helios enables operators to identify areas of inefficiency, receive tailored training, and boost their performance. Through visually representing setup times and identifying specific areas of slowdown, Helios provides targeted feedback, helping operators fine-tune their practices.

FAQS

- Reduce production bottlenecks and

unplanned downtime - Optimize box plant productivity

- Increase asset utilization

- Optimize maintenance intervals and costs

- Automate parts orders

- Predict failures before they occur

- Minimize loss and maximize output

ROI Calculator

Helios Tiers

Remote Monitoring

Most Popular!

Machine Learning Basic

Machine Learning Advanced

Already leveraging a business analytics tool?

Contact Us about integrating your existing systems with Helios machine learning and predictive analytics via the Helios API.

RELATED PRODUCTS

ePS

By seamlessly connecting ePS with Helios,SUN customers now have the power to not only unlock intricate insights into machine settings and patterns but also to transform their operations into a more proactive, efficient, and evolved system.

SUN625HD® Heavy-Duty Rotary Die Cutter

Proprietary, proven systems, specially formatted to maximize printing and heavy duty die-cut assembly and production.