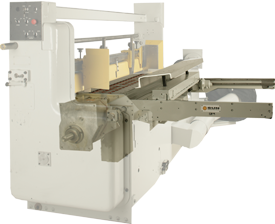

EXTEND-O-FEED®

LEAD EDGE FEEDER FOR ROTARY DIE CUTTERS AND FLEXO FOLDER GLUERS

Durability, Precision, and Versatility for RDCs and FFGs

The Extend-O-Feed® Lead Edge Feeder is a highly accurate, reliable, and versatile front-of line solution for rotary die cutters and flexo folder gluers. With minimal maintenance and up to 20 year lifespans, the Extend-O-Feed® is the machine of choice for thousands of manufacturers worldwide.

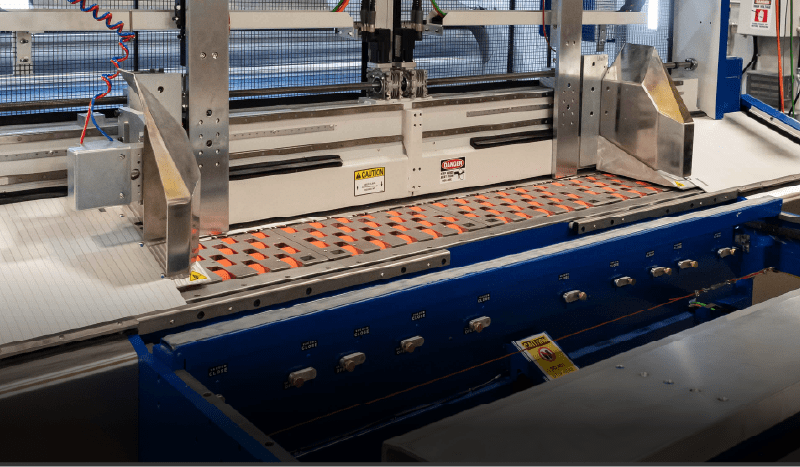

Superior Feed Accuracy

The Extend-O-Feed® ensures precise registration, enabling pinpoint accuracy and significantly reducing the risk of misalignment and subsequent production issues.

High versatility

Designed to manage a wide range of sheet types, including warped sheets, thin flutes, and cross-corrugated sheets, the Extend-O-Feed® maintains control and consistency even in challenging circumstances.

increased efficiency

The innovative design significantly reduces scrap loss due to jams, enhancing overall productivity. Additionally, less time spent on clearing jams results in more consistent production flow.

Minimal maintenance

With maintenance-free transmission systems and low friction metal gate runners, the Extend-O-Feed® boasts a robust design with high-quality components that significantly reduces the need for repairs and downtime.

Easy Interface with Pre-Feeders

The Extend-O-Feed® is designed for straightforward integration with pre-feeders, making it a flexible choice for a wide range of production line.

long-term reliability

The Extend-O-Feed® is built to last, providing exceptional functionality and results for 15-20 years.

FAQS

- Precise registration < +/- .040″ for 90% of sheets

- Matches OEM speeds

- Max out of square not to exceed +/- .025″ when measured over a 2-meter-wide sheet

RELATED PRODUCTS

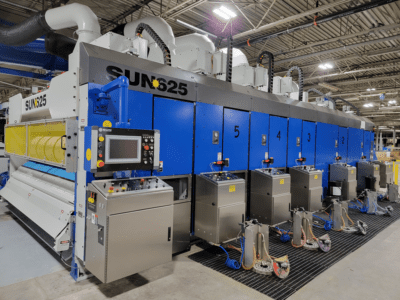

SUN625HD® Heavy-Duty Rotary Die Cutter

Proprietary, proven systems, specially formatted to maximize printing and heavy duty die-cut assembly and production.

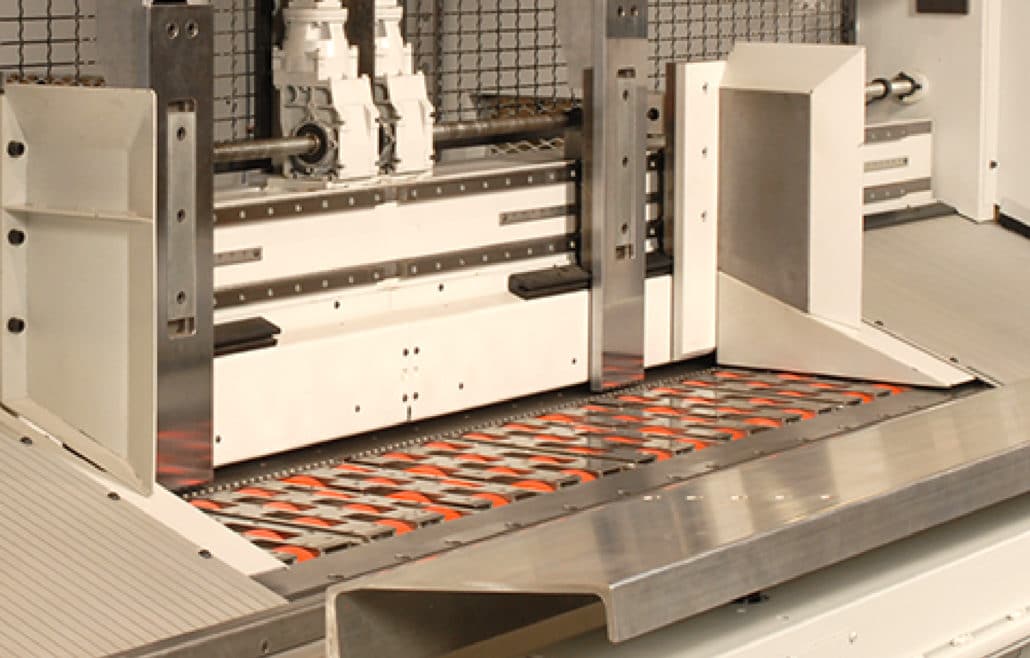

EZ-Cover Replaceable Feed Roll Covers

Our patent-pending covers are replaceable in convenient 10-inch-wide sections, eliminating the need to remove the roll from the machine. This innovation saves time, labor, and resources, and it’s designed for seamless integration into your operations.