MICROGRIND®

Anvil Trimmer

A New Level of Precision & Consistency

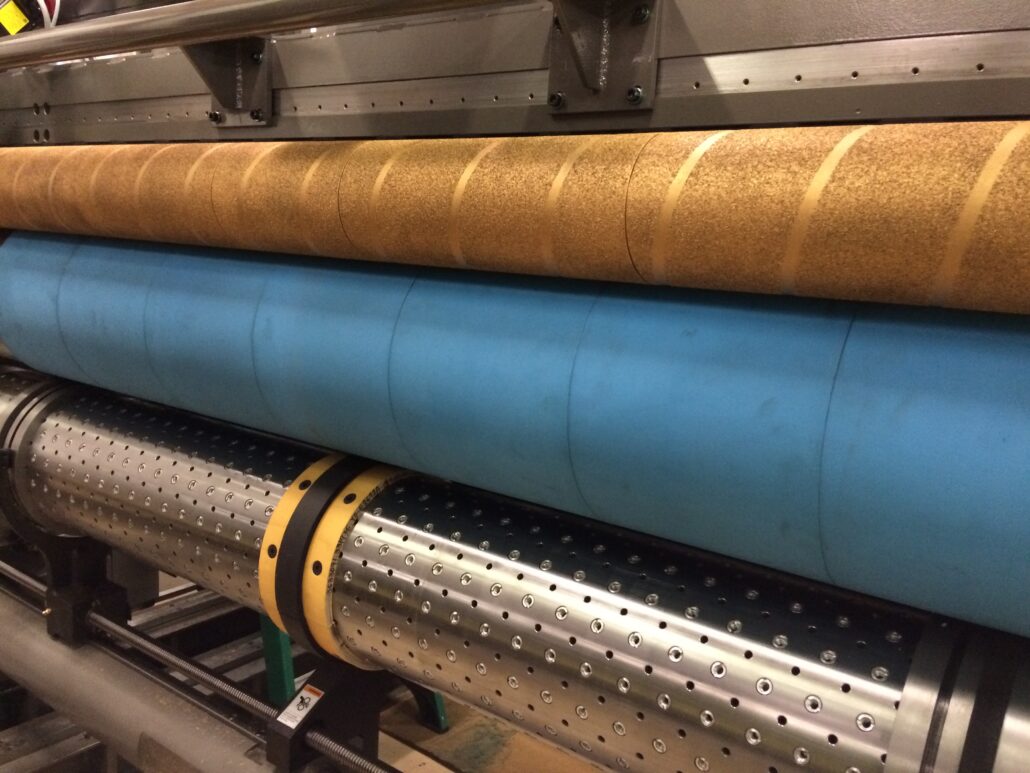

Welcome to the future of precision die-cutting with SUN Automation Group’s MicroGrind® Die Cut Accuracy System. Revolutionizing the industry with its innovative approach, MicroGrind® ensures unparalleled consistency, quality, and efficiency in your die-cutting process, all while reducing the need for operator intervention.

High Precision Cutting

With MicroGrind®, the first die cut board is cut as precise as the last, ensuring consistency across high volume production runs.

increased efficiency

The system automatically removes micro amounts of material every 10,000 impressions without operator intervention, significantly reducing downtime and enhancing productivity.

Consistent Quality

MicroGrind® ensures a consistent cutting and creasing surface throughout the life of the anvil blankets, improving the quality and uniformity of the finished product.

Reduced Maintenance

MicroGrind®’s innovative design minimizes the need for blanket rotation, saving valuable time on routine maintenance tasks.

Durability and Longevity

By promoting a more even wear on cutting dies, MicroGrind® can extend the life of your die-cutting equipment, leading to cost savings over time.

Versatility

Available for both top and bottom anvil applications, MicroGrind® offers a flexible solution that can be incorporated into a wide range of die-cutting operations, making it a versatile tool in the manufacturing process.

FAQS

- Consistent anvil blanket surface

- Minimizes downtime

- Tungsten Carbide grinding roll

RELATED PRODUCTS

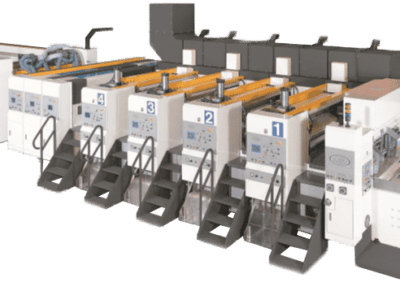

PP-SERIES

With a fixed frame set while run design, dual durometer feed roll, precise creasing options, versatile slotting capabilities, and optional ink systems, the PP-Series is your solution for high-quality packaging production.

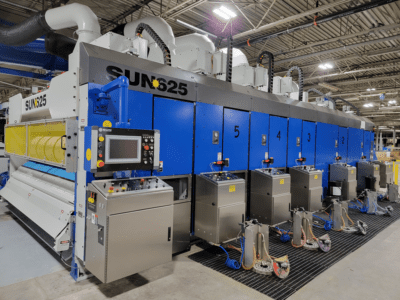

SUN625HD® Heavy-Duty Rotary Die Cutter

Proprietary, proven systems, specially formatted to maximize printing and heavy duty die-cut assembly and production.