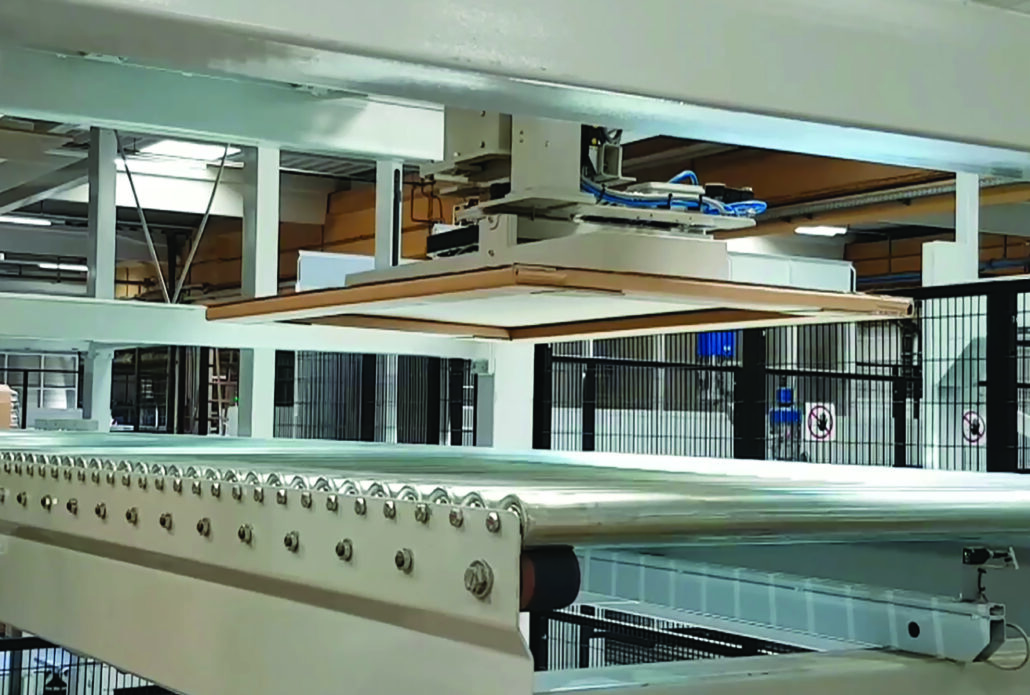

PARA Pallet Inserter

End-of-Line Solution to Improve Output

Automatically Stage, Retrieve and Deliver Pallets

The PARA Pallet Inserter automatically retrieves and delivers up to two pallets at a time at speeds of up to 200 pallets per hour. Equipped with double stacking capabilities and an optional load topper, the high-speed system rounds out PARA’s end-to-end automation solutions by optimizing end-of-line efficiency and accuracy.

100% Automation

The Pallet Inserter is integrated with full ERP automation for operator-free order staging. The system completely eliminates the need for manual operation, significantly reducing labor costs and increasing workplace safety.

high-speed staging

Rated at 200 pallets per hour, even a single Pallet Inserter can effectively service most high-volume plants.

increased efficiency

The Pallet Inserter boasts double stacking capabilities to maximize truck load efficiency and decrease cycle time.

increased protection

The Pallet Inserter can be equipped with a sheet topper made from any material that fits within the machine, adding an extra layer of protection.

FAQS

The Pallet Inserter offers unique double stacking capabilities, meaning two piles can be stacked vertically on the same pallet. The system is equipped with a side stacking system, a lateral folding system for bottom protection sheet, and muting security photocells at product entrance, exit, and physical security perimeter barriers. The system is optionally available with a top sheet inserter that is capable of inserting many different types of materials. The Pallet Inserter is rated at a maximum speed of 200 pallets per hour.

RELATED PRODUCTS

Pre-Feeder

Prefeeder designed for stacking bundles of die-cut sheets in both flatbed and rotary die cutters. This efficient palletizer line comprises an automatic load former that effortlessly stacks medium to large bundles of die-cut sheets.

Vertical Work-In-Progress

With complete automation and a minimal moving parts design, this solution significantly improves accuracy, efficiency, and workplace safety. By incorporating built-in cameras and a static system, it minimizes maintenance requirements and the risk of material handling damage.