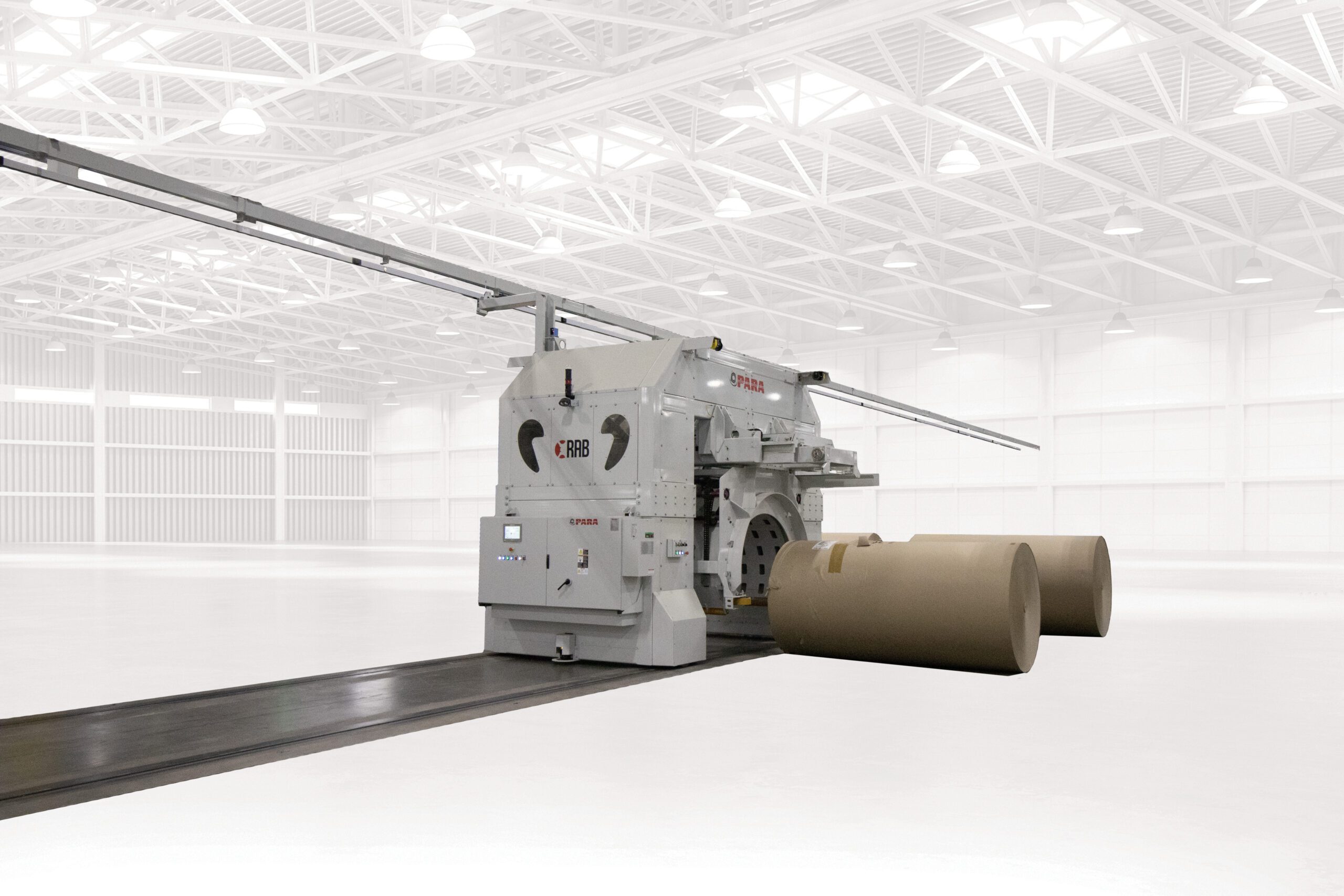

PARA CRAB® System

Efficient Roll Delivery for Your Operation

Improve Efficiency with Automatic Roll Delivery

The CRAB® System offers a tailored solution to enhance roll delivery in the corrugated manufacturing process. Eliminates the need for a clamp truck driver to race up and down the operator side of your corrugator to deliver rolls. This greatly reduces the risk of personnel injury and damage to the paper reels. The CRAB® will interface with your ERP to automatically deliver and even take away rolls. Every time the CRAB® handles the paper reel, it will update the ERP with the linear feet of paper remaining on the roll. When the CRAB® is down for maintenance, a clamp truck can still be used to deliver the paper reels.

Ease of installation and redundancy

The CRAB® System operates with standard flush mount floor track, eliminating the need for major foundation work during the installation and redundancy allowing clamp truck traffic to drive over the tracks and deliver rolls when the Crab is down for maintenance.

100% Automation

From roll stock to corrugator, the CRAB® System can be fully integrated with an existing ERP, removing the need for manual operation.

Improved operator safety

Due to minimal excavation and forklift traffic, the CRAB® System substantially reduces the potential of workplace accidents.

Minimize Structural Changes

Implement the CRAB® system without the need for major structural alterations in your corrugated plant.

Exclusive Service Regions

Find the CRAB® system’s expert sales and service exclusively through SUN in the UK, Ireland, US, Canada, and Mexico.

FAQS

The CRAB System is a fully automated roll delivery system designed to eliminate the safety concern of a forklift racing up and down the side of your corrugator. The CRAB will pick up and transport from a designated drop-off or pickup point and deliver to and from your single facers. The CRAB is seamlessly integrated into your ERP system to deliver and return the rolls, and even stage high-use rolls alongside the corrugator. Every time a roll is picked up or moved, the CRAB measures the lineal feet of paper on the roll and updates your roll stock inventory in real time

RELATED PRODUCTS

Vertical Work-In-Progress

With complete automation and a minimal moving parts design, this solution significantly improves accuracy, efficiency, and workplace safety. By incorporating built-in cameras and a static system, it minimizes maintenance requirements and the risk of material handling damage.

Pallet Inserter

PARA’s Pallet Inserter revolutionizes the end-of-line process, enhancing output efficiency while prioritizing safety and reducing labor costs. With a remarkable capability of handling up to 200 pallets per hour, this system is a game-changer for high-volume plants.