Vertical Work-in-Progress

100% Automation with Minimal Moving Parts

Improve storage capacity and efficiency with fully automatic vertical system

The PARA Vertical WIP Storage System maximizes vertical real estate by efficiently stocking goods in fixed-frame, custom vertical racks. The fully automated system can provide a substantial return on investment for facilities with as little as 25 feet of height, freeing up valuable floor space and improving overall efficiency.

Custom Configuration

The system is built to fit the unique space and needs of each facility, making it a versatile addition to the production line.

improved operator safety

The entire system, including the racking, is static. The only moving parts are the actual T carts, which run vertically and horizontally up and down the aisles to retrieve the Loads from the Corrugator and store them in the vertical storage racks, then deliver the load to the converting machines when they are called by the ERP. This greatly improves operator safety, as it highly reduces the possibility of injury.

100% automation

PARA’s Vertical WIP Storage solution removes the need for manual operators, significantly increasing accuracy, efficiency, and workplace safety.

user-friendly interface

The HMI touch screen allows you to see details about any load stored in the system: who the customer is, how many sheets are in the load, the characteristics of the sheet, the customer that it is designated for, and more.

FAQS

The Vertical WIP System is a fully automated storage solution that leverages vertical real estate to drastically reduce floor space usage. The system is suitable for any industrial environment, allowing for increased space, efficiency, and storage accuracy.

RELATED PRODUCTS

PARA Crab System

The CRAB® System offers a tailored solution to enhance roll delivery in the corrugated manufacturing process.

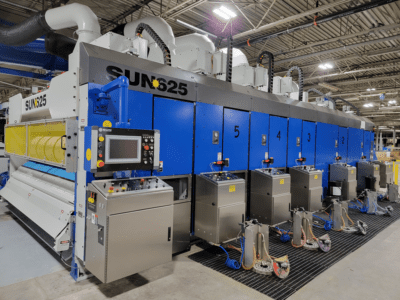

SUN625HD® Heavy-Duty Rotary Die Cutter

Proprietary, proven systems, specially formatted to maximize printing and heavy duty die-cut assembly and production.