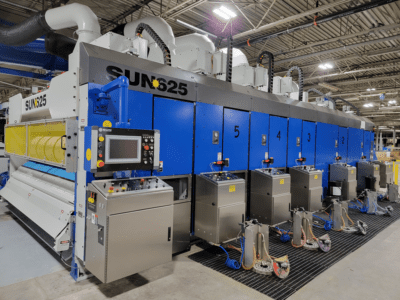

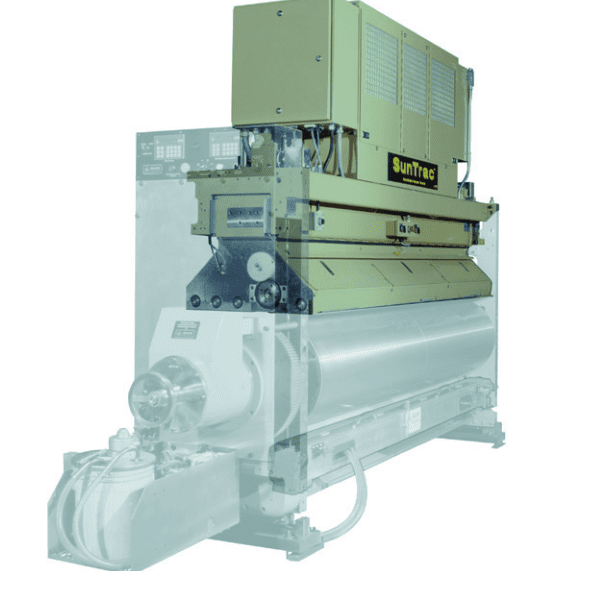

SunTrac®

Vacuum Transfer System

Boosting Quality and Efficiency

Say goodbye to long setup times and high maintenance with the SunTrac® Vacuum Transfer System. By providing the optimum board path and delivering a flat sheet throughout the printing process, vacuum transfer eliminates jams, allows significantly faster operating speeds, and improves print quality.

Increased Productivity

The SunTrac® Vacuum Transfer System allows for significantly faster operating speeds, reducing setup times and improving overall productivity.

Enhanced Quality

By ensuring an optimum board path and delivering a flat sheet throughout the printing process, the system helps improve the print quality and reduces color-to-color register variation.

Reduced Waste

The SunTrac® system can minimize scrap, reducing lead and trail trim, and eliminating the need for edge trim for pull bands and pull collars.

Increased Flexibility

The system can handle a variety of boards, including small flute, warped, and coated boards, enabling you to cater to a broader range of printing needs.

Lower Maintenance Costs

The SunTrac® Vacuum Transfer System replaces many high-maintenance items, reducing repair costs and downtime.

Efficient Setups

The automated print nip adjustment and precise control of the sheet through the machine speed up the setup process, saving time and resources.

FAQS

- E flute – Double wall

- Registration to 1/64″ trap

- Matches speed from OEM

RELATED PRODUCTS

Helios Corrugated IIOT Platform

Helios empowers you with unparalleled data insights, predictive maintenance, and downtime reduction, all designed to optimize your corrugated production processes.

SUN625HD® Heavy-Duty Rotary Die Cutter

Proprietary, proven systems, specially formatted to maximize printing and heavy duty die-cut assembly and production.