The corrugated box is no longer just a simple medium to deliver products from point A to point B. Boxes are now a large part of the consumer experience and expected to be a sophisticated marketing piece. As a result, Corrugated Printers are quickly adapting to the complex needs of this new market to stay competitive. As the demand for higher quality print continues to grow, Converters have turned to chamber manufacturers to achieve the precise, controlled ink metering needed for high quality print.

Currently, there are 3 types of corrugated ink systems: a roll-to-roll ink system, a single doctor blade system and a dual doctor blade system. Converters who do not require any process work typically have no issues using a 2-roll ink system to achieve the flood coating or block letter printing. However, Converters seeking to diversify their product portfolio and improve print quality should consider switching to an ink system that utilizes a doctor blade.

In this blog post, we’ll focus on single blade ink systems and the advantages and disadvantages of this technology. We’ve considered the same for dual blade ink systems in another blog published here: LINK.

Single Blade Ink Systems

A single blade ink system is an open ink system, with one doctor blade installed for metering the anilox roll. Single blade ink systems require an ink pan directly below the system to catch the run-off ink, which is then filtered and pumped back into the system.

Advantages

Single doctor blade ink systems have become increasingly popular among Corrugated Converters today for many reasons. For starters, they cost much less than their dual-blade counterparts and are capable of effectively metering a variety of print applications: higher line screen process work, block lettering, flood coats etc. Printers also spend less money on consumables– only one blade is required and no end seals are needed in single blade systems. In addition, the open design allows for easier access for wash ups, decreasing clean times and therefore increasing press uptime.

Disadvantages

Although single blade ink systems are the popular choice of blade systems, there are some downfalls to this ink-delivering technology. The most obvious disadvantage is the fact that the system is open, therefore exposed to the surrounding environment. If you’ve walked through a corrugated plant, then you know it can be a hostile setting for your ink. Dust, dirt, debris and scraps have easier access to an open system (single blade or roll-to-roll) and can cause hickeys and other defects within your print, as well as disruption within your ink pumps. The open system also makes it difficult to maintain ink viscosity, resulting in a breakdown in pigments and the need for possible amine additives. Another disadvantage is the potential ink waste. With a single blade system, ink residue is not only found within the ink cavity, but also within the ink pan, causing more waste than what you would expect from an enclosed chamber.

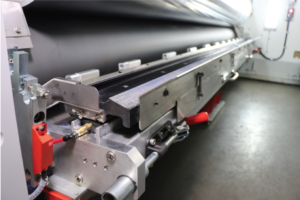

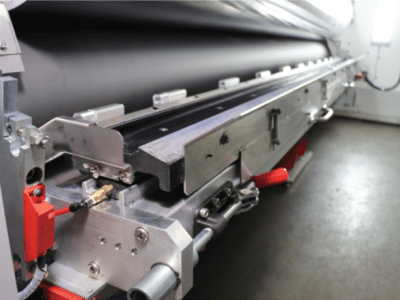

ColorMaster® Single Blade Ink System

For facilities producing a wide variety of orders – flood coats, process work, and block lettering – we recommend a single blade ink system. The capabilities of these systems are flexible and can effectively and efficiently meter an assortment of print jobs.

Sun Automation Group manufacturers an economic and versatile single blade ink system for Corrugated Printers – ColorMaster®. The ColorMaster® Single Blade Ink System is lightweight, corrosion resistant and economically designed to improve ink metering for printers worldwide. The design of the ColorMaster® combats some of the traditional disadvantages of a single blade ink system. ColorMaster® is equipped with a stainless steel shield to effectively shelter your ink from dust and debris, maintaining ink integrity and improving print quality. The ColorMaster® base assembly and SST ink pan (between frames) and all of its options are sold separately, so you can purchase only what is required. Even more, with our fleet of service technicians and coordinators, SUN can retrofit your machines with the ColorMaster® Ink System with limited downtime.

Ready to delight your customers with higher quality print? CLICK HERE for more information on the SUN ColorMaster® Single Blade Ink System, and to request a quote.

SUN AUTOMATION GROUP PROMOTES NEW DIRECTOR OF SALES IN NORTH AMERICA

SUN AUTOMATION GROUP PROMOTES NEW DIRECTOR OF SALES IN NORTH AMERICA