eProductivity Software (ePS)

MES, ERP and Process Controls

Empowering Growth and Conquering Challenges

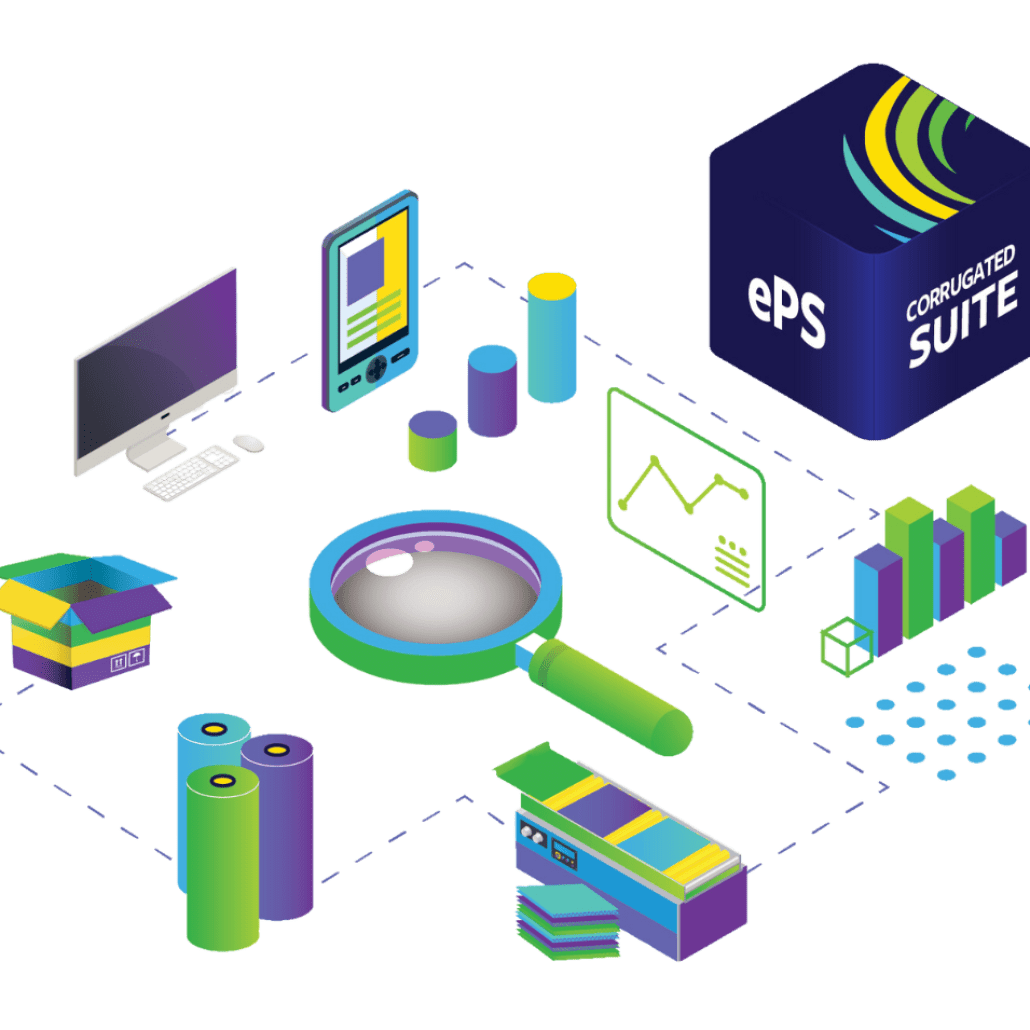

ePS and SUN Automation Group® have embarked on a significant partnership to bring transformational technology to North America’s corrugated sector. This partnership introduces ePS’ Corrugated Suite, aka CorrSuite, a comprehensive suite of industry-specific ERP (Enterprise Resource Planning) and MES (Manufacturing Execution Systems) technology solutions, and Escada, a closed-loop corrugator process and Quality Control System (QCS), to North American corrugated board and box manufacturers. Together, ePS and SUN Automation aim to enhance efficiency, productivity, and operational excellence in an ever-evolving industry.

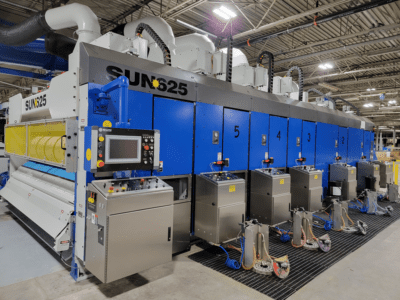

new life for aging machinery

ePS’ Escada corrugator QCS and process control is a ‘closed loop’ system that enables manufacturers to optimize their existing equipment, increase run speeds, and produce high-quality board consistently without the costly investment of new equipment.

elminiate redundancies and bottlenecks

CorrSuite is designed to optimize your operations, enabling unparalleled efficiency and productivity. From order management to production planning and inventory control to quality assurance, CorrSuite integrates every aspect of your corrugated workflow, eliminating redundancies and bottlenecks.

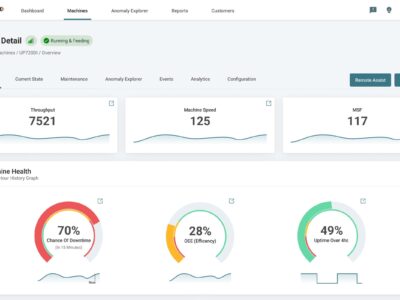

Breakdown Prediction

Escada’s Reliability module is a predictive maintenance module that alerts operators when assets are due to renew or require service attention. Predictive maintenance ensures minimal disruptions and improves corrugator and overall equipment efficiency and reliability.

Exceptional Support

SUN Automation’s exceptional 24/7 on-site technical support complements ePS’ technology solutions, providing comprehensive customer care.

INTELLIGENT SCHEDULING

Leveraging intelligent algorithm scheduling, this collaboration helps corrugated businesses adapt to dynamic environments and fluctuating demands. The flexibility of CorrSuite’s MES modules supports both forwards and backwards (push vs pull) scheduling abilities, facilitating efficient scheduling, allowing planners to create the lowest-cost production schedules, effectively balancing inventory levels, and sequencing orders.

REAL-TIME PLANT FLOOR VISIBILITY

With plant floor visibility, manufacturers can collect real-time data, streamline QA processes, make informed decisions, and monitor operations more effectively.

FAQS

RELATED PRODUCTS

SUN625HD® Heavy-Duty Rotary Die Cutter

Proprietary, proven systems, specially formatted to maximize printing and heavy duty die-cut assembly and production.

Helios Corrugated IIOT Platform

Helios empowers you with unparalleled data insights, predictive maintenance, and downtime reduction, all designed to optimize your corrugated production processes.