Helios uses a variety of terms related to IIoT, AI and Machine Learning on a regular basis, and some of these terms may not be familiar to everyone in the corrugated industry. You’re bound to come across terminology and acronyms that are not clear. We’re here to help. We\’ve created this glossary of key terms to help you better understand what they mean.

- Artificial Intelligence (AI) – A broad field of computer science concerned with creating intelligent machines capable of performing tasks that normally require human intelligence. In the case of Helios, intelligent insights derived from data point sources assist operators in reducing unplanned downtime and optimizing box plant production operations.

- Advanced Predictive Analytics – Predictive analytics is the use of artificial intelligence and machine learning to crunch massive datasets, recognize patterns within them, and predict the likelihood of outcomes. Predictive analytics can be used to reduce downtime in a variety of industries, including manufacturing, packaging, and corrugated.

- Abnormal Machine Operations – A state of a manufacturing facility in which a significant event or condition, whether planned or unplanned, adversely affects, potentially affects, or indicates deterioration in the safety, security, or performance of equipment.

- Agnostic – Agnostic refers to hardware or software that can be used on a variety of platforms or operating systems from a technological standpoint. Helios is PLC- and OEM-agnostic, which means it may be used on a variety of corrugated converting equipment models and control systems.

- Algorithm – An algorithm is a process or a set of rules that a computing software follows in problem-solving and machine learning applications. A machine learning algorithm is a method by which an AI system predicts output values from input data. The Helios data analysis team trains the algorithm to specifically mine data and learn from every client’s specific, unique corrugated converting machines. Organizations that adopt this refined, unique, customized solution stand to gain enormous benefits.

- Anomaly Detection – Any method for locating outliers in a data set. These abnormalities could point to unusual behavior in operational, tooling, or mechanical processes. Helios can detect a faulty feed roll cover, paper jams, print registration difficulties, journal failure, or simply highlight maintenance needing to be performed in a corrugated application.

- Application Programming Interface (API) – an API allows smart computers and applications to communicate with each other, allowing manufacturers to seamlessly communicate performance data with outside stakeholders. APIs are positioned between a smart application and a web server, acting as an intermediary to process data transfer between systems.

- Automated Manufacturing Technology – Technology that is used by manufacturers to produce quality products faster and more efficiently. These computerized control systems help to optimize equipment in a facility where products are produced, such as a corrugated converting box plant.

- Automation Control Process – A process used to autonomously control the manufacturing conditions of a product, resulting in greater quality and efficiency. Continuous production in corrugated facilities, where corrugated material is processed into a product without interruption, employs process control.

- Computerized Maintenance Management System (CMMS) – Software that centralizes maintenance information and streamlines maintenance operations. It helps box plants optimize the usage and availability of corrugated conversion equipment such as Rotary Die Cutters, Flexo Folder Gluers, Material Handling Systems, and other assets.

- Corrugated Converting Equipment – A group of machines that produce finished product (boxes) from corrugated boards by cutting, scoring, folding, gluing, slotting, and/or printing.

- Cycle Time – The length of time required to accomplish a certain task from start to finish in production. This critical KPI takes into account both the time spent creating an item and the time spent waiting between active working stages. In a setting such as a corrugated converting box plant, automated manufacturing technology is helping reduce cycle times.

- Condition Monitoring – Monitoring a condition parameter in industrial machinery to detect a substantial change that could suggest an anomaly or the development of a malfunction. It is a critical component of predictive maintenance and a major part of how Helios helps to increase corrugated conversion equipment uptime.

Corrugated Industrial Internet of Things (IIoT) Platform – Artificial intelligence and machine learning technology for a corrugated factory floor, offering actionable information to help optimize fleet operations and maintenance tasks. Helios is the first IIoT platform developed for the corrugated industry by experienced corrugated professionals. - Data Security – The technique and practice of safeguarding digital data against unauthorized access, corruption, or theft. This can include safeguarding against aggressive cyberattacks and data breaches, including those caused by human error. Helios has made data encryption one of its key best practices for safeguarding digital data, such as those in a database, against damaging forces and the undesirable actions of unauthorized users. When data is transmitted between sources as well as when it is at rest in the database, we use encryption. Helios\’ \”cyber-first\” development process means that everything constructed and engineered is done from the start with a security-conscious perspective.

- Digital Transformation – The use of technology and data to extract useful information that allows manufacturers to reduce costs, optimize capacity, and keep downtime to a minimum. This is also known as the Industry 4.0 transformation in the corrugated, manufacturing, and packaging industries.

- Downtime – Any length of time during which manufacturing output is halted. Downtime can be scheduled or unplanned, with the former being caused by routine maintenance or job changeover and the latter by equipment failure or other unexpected events. Causes of this in corrugated converting include technical failure, machine adjustment, maintenance, or a lack of inputs like materials, manpower, or electricity.

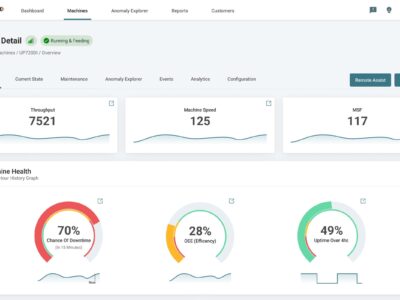

- Helios – The corrugated industry’s IIoT and Machine Learning platform. Helios works with corrugated converting equipment to detect anomalies in operations, such as an unusual noise or an unexpected vibration, and provides a corpus of data that machine learning algorithms can analyze. Over time, this information can be utilized to detect possible faults and inefficiencies that even the most experienced operators would miss with the naked eye.

- Industry 4.0 – The Fourth Industrial Revolution, also known as Industry 4.0, envisions a rapid change in technology, industries, and societal patterns and processes in the twenty-first century as a result of increased interconnectivity and smart automation tools like Helios.

- Lean Manufacturing – Lean Manufacturing is a production system that strives to eliminate waste from all of its activities and operations to produce products and deliver services on time with as few resources as possible. Key pillars of lean manufacturing include creating products better, faster, and cheaper than competitors, all while reducing as much waste as possible.

- Machine Learning (ML) – The process and application of AI by which smart computers, hardware and software, use collected data and intelligent algorithms to provide progressively precise insights, predictions, and decisions. Machine learning algorithms may be educated with sample data and then use takeaways from that data to make increasingly accurate predictions and judgments without having to be explicitly programmed to perform each unique action.

- Manufacturing Execution System (MES) – On a manufacturing floor, these systems connect and monitor machines and equipment. Quality and efficiency-enhancing software solutions are embedded into the corrugated manufacturing process and are aggressively and systematically enforced.

- Maximized Operational Efficiency – Can be accomplished by reducing waste and pursuing optimized business practices with resources such as time, people, equipment, inventory, and money. Changing market trends, management practices, and human error all contribute to inefficiencies in the corrugated converting industry and can all be mitigated, if not totally removed, from the business process.

- Neural Networks -Machine learning networks that function similarly to the human nervous system. They are a method of performing machine learning in which algorithms collaborate to examine incoming data and deliver the most relevant information.

- Overall Equipment Efficiency (OEE) – A \”best practices\” metric for determining the percentage of planned production time that is actually productive. A perfect OEE score of 100 percent represents perfect production: making only good parts as quickly as possible with no downtime. OEE is calculated as (Good Count × Ideal Cycle Time) / Planned Production Time

- Predictive Monitoring – Predictive monitoring is a machine learning method in which artificial intelligence analyzes data from manufacturing equipment and alerts operators to anomalies, breakdowns, and other downtime events before they occur. By spotting abnormalities before they become problems that create unplanned downtime, predictive monitoring in a corrugated converting operation may ensure that your machinery is always available. By enabling you to improve production reliability, Helios allows you to concentrate on what is most important: your customers and their jobs.

- Predictive Maintenance – Predictive maintenance is a result of machine learning, in which artificial intelligence with predictive monitoring capabilities notify operators of normal and emergency maintenance actions before they occur. This can help to maximize resource use while also anticipating failures before they occur.

- Process Improvements – Refers to critically thinking about and improving the processes that contribute to the final product of a manufacturing operation. This evaluation can help to reduce defects, shorten production time, and increase customer satisfaction. Thorough process improvements are one of the most effective ways to improve quality, operational efficiency, and bottom-line results.

- Real-Time Corrugated Machine Monitoring – Monitoring machine performance in real-time, with the correct technology, helps manufacturers to discover anomalies, respond swiftly, and allows operators to prevent machine failures before they occur. Helios is designed for corrugated converting machines to reduce downtime, boost profitability, and reduce the expenses associated with unwanted downtime and maintenance. The OEM-agnostic corrugated platform is designed to provide manufacturers with strong, real-time, actionable data regarding the performance of your equipment.

- Remote Monitoring – Remote monitoring in a manufacturing scenario is performed through the use of IIoT and artificial intelligence-based technology to track machine performance, output, and abnormal behavior. Sensors monitor the functioning and productivity of corrugated machines and feed data to a machine learning system, such as Helios, which analyzes the data and delivers real-time insights to operators. At any time, your staff may obtain real-time data on any machine on your production floor, as well as complete reports on how your machines are performing over time, including information on whether a breakdown is approaching.

- Sensor – An IIoT-enabled device that monitors real-time data from manufacturing equipment and can interface with a machine learning platform to transform data points into actionable insights. Sensors can be added to existing equipment as part of the Industry 4.0 revolution, giving the same tracking and monitoring capabilities through IIoT platforms without the need to invest in new machinery.

- Smart Manufacturing Technology – The use of sensors to collect data on the operational status and performance of machinery as a part of the Industrial Internet of Things (IIoT). Analyzing data from an entire box plant\’s worth of machines, or even multiple facilities, with Helios allows you to look for signs that specific parts may fail, allowing preventive maintenance to avoid unplanned downtime on corrugated converting equipment.

- Supervised Learning – Supervised learning algorithms, given a collection of observations, model the relationship between features (independent variables) and a label (target). The model is then used to predict the label of additional observations based on the features.

- Unsupervised Learning – Unsupervised learning algorithms seek structure in unlabeled data. These algorithms discover hidden patterns or data groupings without the need for human intervention.

Three Ways AI and Machine Learning Can Help Solve Your Labor Shortage Issues

Three Ways AI and Machine Learning Can Help Solve Your Labor Shortage Issues